![]() Shortage of Chips

Shortage of Chips

Recently a very small device has created much havoc in the auto industry. The production of vehicles across the nation has been stalled due to a shortage in semiconductor chips (LaReau, 2021). Semiconductor chips are made from silicon, which is found in many minerals on earth’s surface. These chips are the reason electrical devices can function. Depending on how intricate, one car part could use anywhere from 500 to 1,500 chips alone (LaReau, 2021). Imagine how many would be needed to assemble an entire car.

This shortage stems from a few different issues, the biggest being the increased demand for personal electronics like cell phones and laptops during the pandemic (LaReau, 2021). With a limited number of factories making these chips, combined with the lengthy production process, suppliers have not been able to keep up with this increased demand (Whalen, 2021).

Not only are there limited factories, but also limited workers. During the pandemic, there has been an inability to maintain a satisfactory number of workers in the plants (Whalen, 2021). Without workers, the plants have been unable to run at full capacity and, therefore, are producing less chips than usual.

The shortage is predicted to cause a loss of $210 billion revenue for this year alone and potentially 1.28 million less vehicles produced. Some factories had to halt vehicle production and customer’s vehicle orders have been delayed (LaReau, 2021). The auto industry was forced to adapt very quickly.

What Companies are Doing

When the shortage first occurred, thousands of vehicles already produced that were awaiting chips were parked in lots before being sent to car dealerships (LaReau, 2021). As time went on and cars began filling the lots, companies realized a short-term solution must be developed fast.

Automakers have been forced to cut production of certain vehicles. They started by producing less of cars with lower demand or cars that aren’t as profitable. Not only this, but some companies have even rid of key features to reduce the number of chips needed in vehicles. For example, Tesla removed their passenger side lumbar support and GM took out some fuel-saving features (LaReau, 2021). This allowed for the production of these vehicles to continue during the chip shortage.

Few companies have even taken the step to start producing new chip factories themselves. This avenue may be a solution for some; however, these factories can cost up to $10 billion or more (Whalen, 2021). This solution, while promising, is unappealing to most companies due to the high investment cost.

To counter these losses companies are experiencing, prices for vehicles have greatly increased. Many are searching for ways to decrease their expenses (LaReau, 2021). Long-term solutions are currently in the works. Automakers are studying their supply chains and looking for potential improvements (LaReau, 2021). This study has led to predictions of other upcoming shortages.

Future Shortages

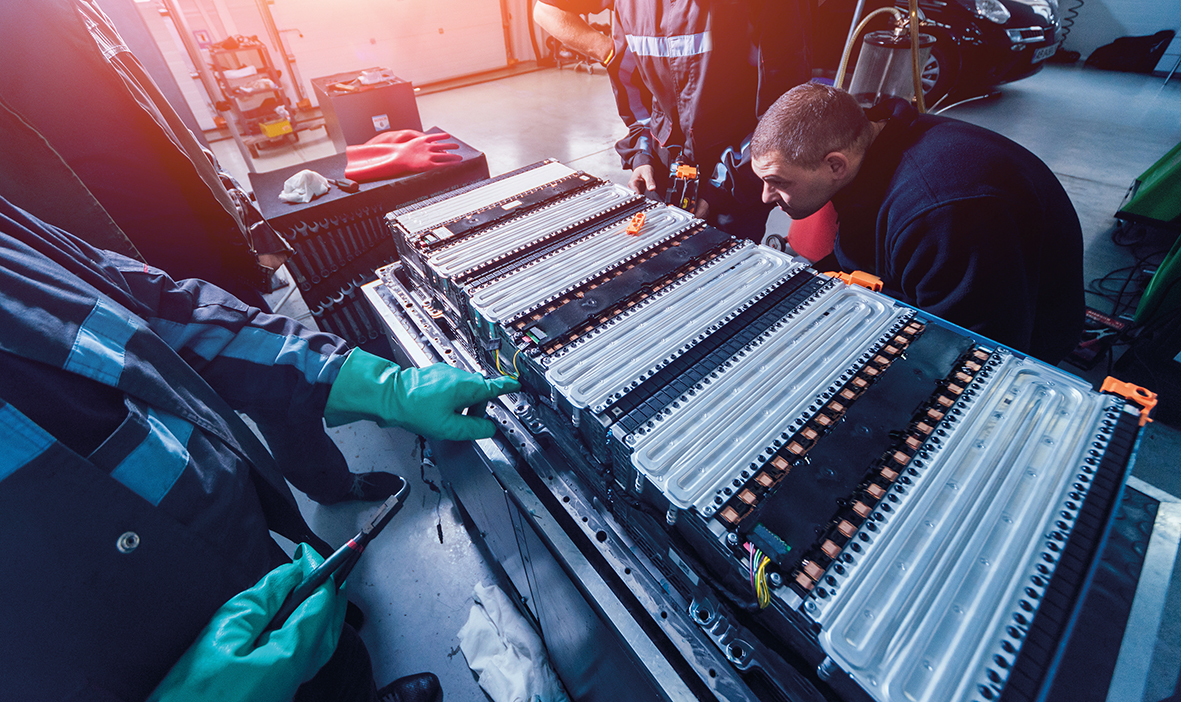

The shortage of chips highlights the current issue within automotive supply chains and helps experts predict another future crisis. It is expected that the next shortage could be concerning lithium-ion batteries (Brigham, 2021). It is known that electric vehicle production is ramping up rapidly, and batteries to support those are going to be needed (Domonoske, 2021).

Although lithium itself is not scarce, the challenge is meeting lithium production with our current technology and regulatory requirement (Castelvecchi, 2021). Because this is not the first shortage the auto industry has seen, companies are more prepared to adapt and recover this time.

Overcoming the Shortage

Overcoming the Shortage

To combat this future issue, companies like GM are announcing new battery production facilities (Szczesny, 2021). However, even with the increase in battery production plants, this effort alone will not be enough.

Scientists turn their attention to reducing the amount of scarce metal in car batteries along with improving the battery recycling process (Castelvecchi, 2021) Reducing the amount of scarce metal inside batteries will make producing them more easily accessible. Improving the recycling process will allow for more materials to be available for production.

While looking for new ways to obtain more batteries, companies are also trying to reduce their dependence on one individual supplier. The end goal being to create more reliable and localized supply chains (Szczesny, 2021).

New processes are also on the horizon. Companies like BMW and Volkswagen have announced agreements with lithium mines to source their own raw materials directly (Domonoske, 2021). This way, they won’t have to rely on other companies to secure the raw materials they need. More modern technology is also underway. Geothermal energy from water to power the procedure of securing lithium is planned to be employed (Castelvecchi, 2021).

With new practices such as these being invented every day, the auto industry is becoming prepared for this lithium-battery shortage. Analyzing current flaws in the supply chain and adjusting current practices can make a huge difference.

Sources:

Brigham, K. (2021, September 14). The U.S. is facing a lithium-ion battery shortage as electric vehicle production ramps up. CNBC.

Castelvecchi, D. (2021, August 17). Electric cars and batteries: How will the world produce enough? Nature News.

Domonoske, C. (2021, April 8). If World’s battery supply doesn’t scale up, automakers will be in trouble. NPR.

LaReau, J. L. (2021, September 23). Everything you need to know about the chip shortage that’s plaguing automakers. Detroit Free Press.

Szczesny, J., says:, J., & *, N. (2021, July 22). Automakers facing potential EV battery shortage as early as 2025. The Detroit Bureau-The Voice of the Automotive World.

Whalen, J. (2021, July 29). Semiconductor shortage hammering automakers, costing billions in lost production and sales. The Washington Post.