Comprehensive Battery Solutions to Meet the Growing EV Market Demands

Vayan’s Lithium Ion/EV solutions are leading the Battery Quality market with customized services that are tailored to meet the exponentially growing demands of the EV transition. Whether it's component inspection and rework, high voltage battery repairs and technical services, off-site battery storage, or component processing and aggregation, Vayan provides end-to-end battery solutions that maximize customer value and enable the EV industry transformation.

Trust us for unparalleled expertise and support in battery services.

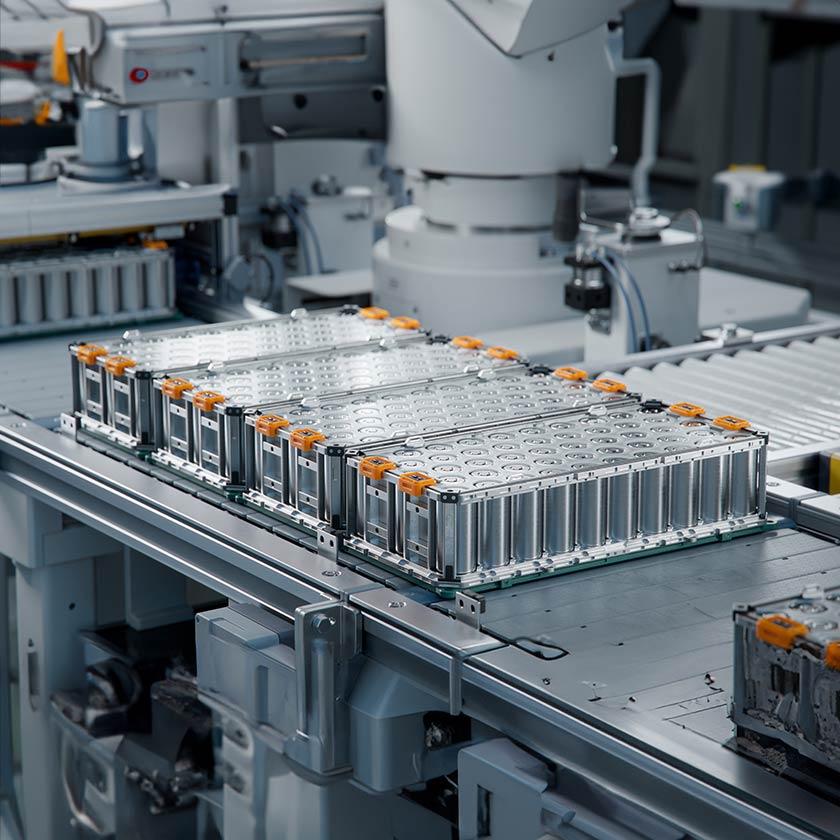

QUALITY INSPECTION, REWORK & SORTING

HIGH-VOLTAGE BATTERY TEARDOWN AND REPAIR

OFF-SITE BATTERY STORAGE & SERVICES

COMPONENT PROCESSING AND AGGREGATION

TECHNICIAN TRAINING & CERTIFICATION PROGRAM

Quality Inspection and Rework

We support high-volume production environments and rapid ramp-ups for OEMs. Vayan has a trained high-voltage certified engineering and technician program that can support various solutions for our customers. We can provide varying levels of inspection from Level 1 visual checks to more technical and qualifications-based inspections - including cell quality, electrical connections, and electrical testing. We offer:

- Visual checks

- Cell inspection for quality

- Electrical connection and electrical checks

- Sorting and testing

- Validation and documentation

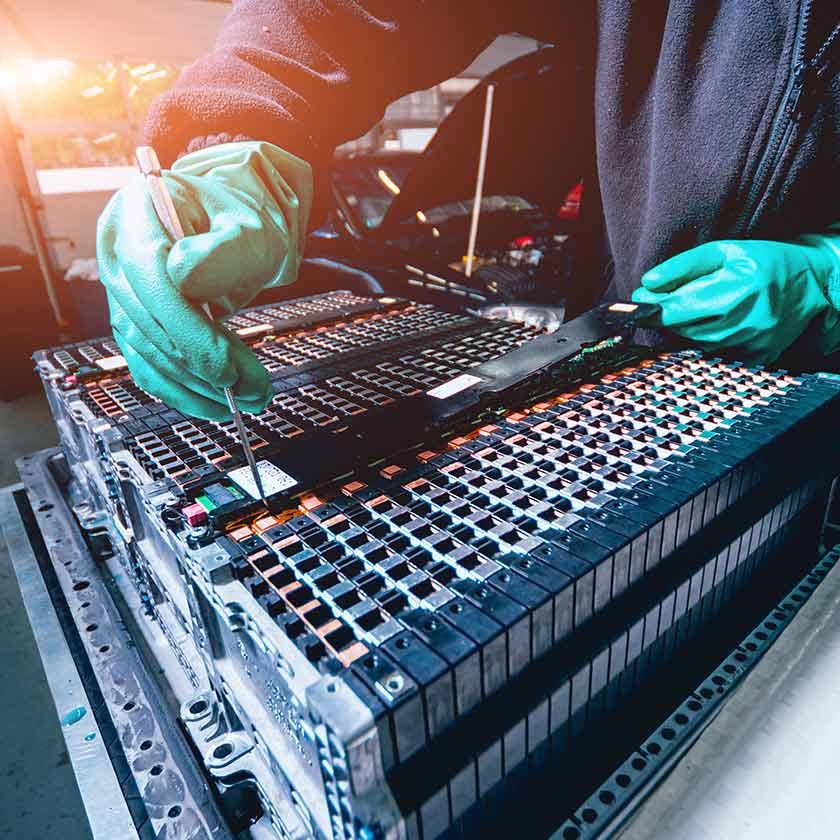

Lithium Battery High-voltage Module / Battery Pack Teardown, Repair and Technical Services

The manufacturing of battery cells and assembly of battery packs is a complex electro-chemical process that requires strong controls and monitoring during the build process. This process can present multiple failure modes.

Vayan technicians can troubleshoot and repair all facets of these manufacturing processes including coolant line blockage, electrical connection failures, harness repairs, cooling plate, sealant issues, module failures, etc. We can provide onsite or off-site remediation services to minimize production losses, ensure validation during launch, and ensure a smooth ramp-up. Industry data shows that scrap costs for new battery startups can range up to 40% of overall cost. Vayan provides fast response problem resolution and feedback to customers to ensure clean points, process changes, and root causes are resolved in the manufacturing or design process. Our capabilities include:

- High voltage battery pack teardown and repair

- Battery safe teardown and disassembly

- Internal component rework including HV harnesses, connections

- Module OCV checks and remediation

- Battery reflash and software updates

- Engineering services

- Process testing, process controls and analysis

Off-site battery storage and technical services

Real estate and safety implications of battery storage can introduce risk and space constraints for OEMs and battery manufacturers. Vayan has regional warehouses at key locations certified and approved for battery storage, giving customers the ability to flex their space requirements during peak times or to manage quality holds. Our warehouses are equipped with facilities to do battery pack teardown, disassembly and assembly, and our inventory management services are streamlined to ensure safe storage. Our certified and well-prepared team members work with a safety-first mindset and our processes are integrated with safety training and continuous monitoring to ensure that batteries are always in safe hands. We offer:

- Storage and warehousing

- Battery OCV testing

- Battery pack repair and testing

- Seamless distribution and traceability

Component processing and aggregation

Vayan does not recycle batteries, but we provide a variety of services in the lifecycle of a lithium battery.

We can disassemble all components of the battery pack and segregate them for the material review and disposition process. We can also assist with transportation and serve as the conduit between manufacturers and recyclers. We transport by road/rail/sea/air while complying with all federal regulations for safe transit.

We also offer the following packaging and shipping quality assurance checks according to the needs of the customer:

- 3rd party verification services

- Shipment validation for DoT, IATA, CFR requirements

- Supplier quality checks for recyclers

- Data collection & analysis