Keep the line moving.

Hit your quality targets.

Flex when demand shifts.

Vayan-At-A-Glance

Tenured Partner to Leading OEMs & Tier 1 Suppliers for 45+ years

±30% headcount flex in ≤48 Hours

≤10 min from defect to Executive Dashboard

50% faster launch containment vs. staffing-only baselines

A Range Of TICC Capabilities

We deliver testing, inspection, certification & compliance through standardized, IATF/ISO-based work—plus digital traceability—so plants stay compliant while moving faster.

Standard work aligned to IATF/ISO with continuous-improvement loops

Embedded teams of certified inspectors/techs/engineers

Unified quality records and workflow automation for audit-ready traceability (QRS + dashboards)

What We Do

Proactive launch gating + reactive containment with cost-certain playbooks to protect SOP and throughput.

Rework & Finished-Vehicle RepairOn-site or off-site remediation to keep schedules intact and reduce scrap/warranty costs.

Design Validation & Supplier DevelopmentAPQP development & rescue, FMEAs, and metrology support to prevent escapes upstream.

Vayan Flex (Labor Strategy)Convert fixed Quality headcount to a flexible, performance-tied model.

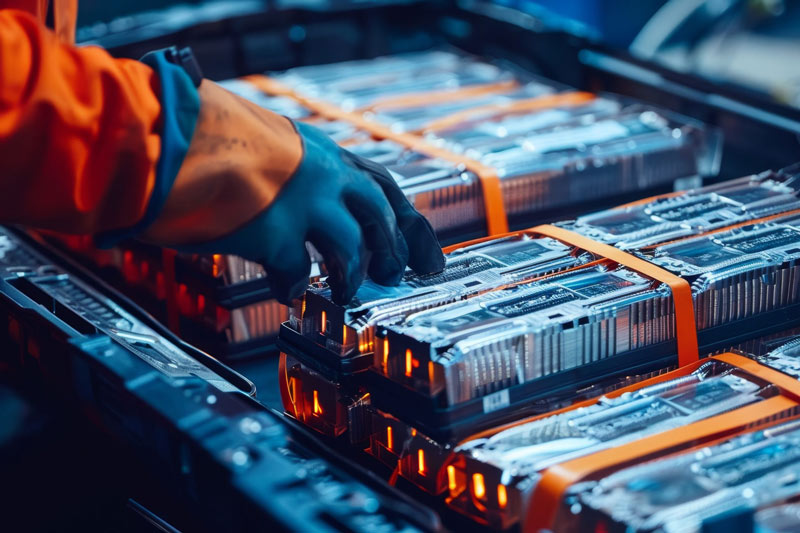

Electrification ServicesBattery teardown/testing/storage, LV/HV harness retrofits, and module re-flash at scale.

Yard Management & FTZ LogisticsRFID tracking, batch & hold, protective wrap, export-friendly flows.

Quality Intelligence Platform / QRSReal-time dashboards, workflow automation, open APIs to ERP/MES, role-based governance, and audit-ready traceability.

How It Works

- Embed & Stabilize

Stand up on-site coverage and standard work; convert fixed headcount to Flex where helpful.

- Instrument the Floor

Turn on QRS + dashboards for live defects, cost, photos, and escalations.

- Orchestrate Launch & Containment

Apply Safe Launch/CS playbooks and unify data across suppliers.

- Expand to Electrification & Yard/FTZ

Pull in battery, harness, re-flash, and yard flows as needs arise.